UK Warns Ships Of Imminent Military Threat In Gulf Waters Amid Rising Tensions

June 12, 2025

UN Demands Global Action To End Ocean Exploitation And Pollution

June 12, 2025

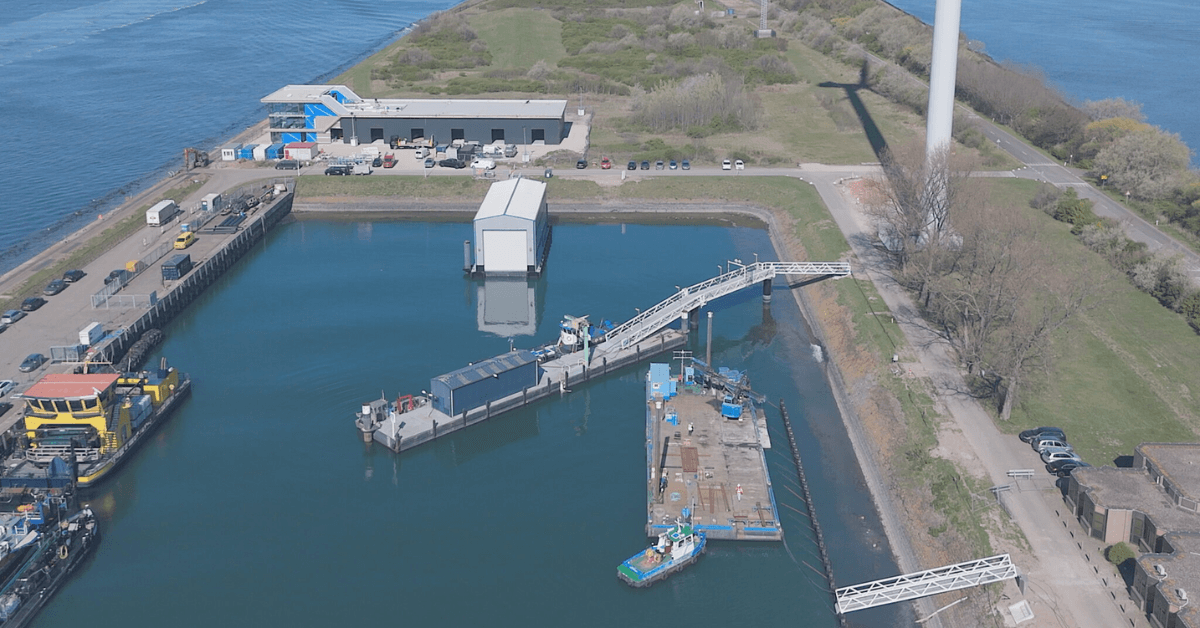

Dutch firms Hakkers and Paebbl have launched the world’s first port infrastructure project that actively stores carbon dioxide (CO₂). The pilot project, located in the Port of Rotterdam, uses innovative materials that reduce emissions and trap CO₂ inside construction mixtures.

The project involves a partial replacement of traditional cement used in anchoring with Paebbl’s carbon-binding material. About 15% of the cement in the anchoring mixture was swapped with this new material.

As a result, around 110 kilograms of CO₂ are captured per ton of the material used. In total, the project locks away approximately 500 kilograms of CO₂.

Hakkers is a well-known Dutch construction and engineering company that uses about 5,000 tonnes of cement every year for anchoring in civil engineering projects. This represents roughly 20% of the Dutch market in this segment.

The company has now taken a big step to lower its carbon footprint by partnering with Paebbl, a tech firm that turns captured CO₂ into long-lasting construction materials.

The project also used fully electric drilling equipment, which helped cut direct emissions on-site and reduce air pollution. Hakkers had already committed to clean and emission-free construction through its sustainability goals.

A manager at Hakkers shared that the company is constantly looking for new ways to reduce its carbon footprint on a large scale. They said traditional anchoring methods depend heavily on cement, which contributes significantly to CO₂ emissions. Through this collaboration with Paebbl, Hakkers is now exploring a more environmentally friendly solution.

According to industry research, the production of cement is responsible for around 8% of global CO₂ emissions. Paebbl’s material offers two key advantages, it permanently stores captured CO₂, and helps lower the overall “embodied carbon” of construction materials.

The company claims that for every 1,000 kilograms of material produced, up to 300 kilograms of CO₂ can be stored. When used as a partial cement replacement, this material has the potential to reduce construction-related emissions by up to 30%.

Paebbl achieves this by speeding up the natural mineralisation process by a factor of one million. This process turns CO₂ into a stable mineral form, keeping it out of the atmosphere. By embedding carbon into construction materials, buildings and infrastructure can shift from being sources of emissions to actually storing carbon, turning them into potential CO₂ sinks.

A senior Paebbl official said they were excited to see their technology applied in real-world projects.

Reference: Hakkers

Source: Maritime Shipping News