MPA & Port Of Rotterdam To Decarbonise & Digitalise One Of World’s Busiest Trade Routes

March 27, 2025

NTSB Determines Cause Of $4.5 Million Terminal Cargo Crane Damage In South Carolina

March 27, 2025

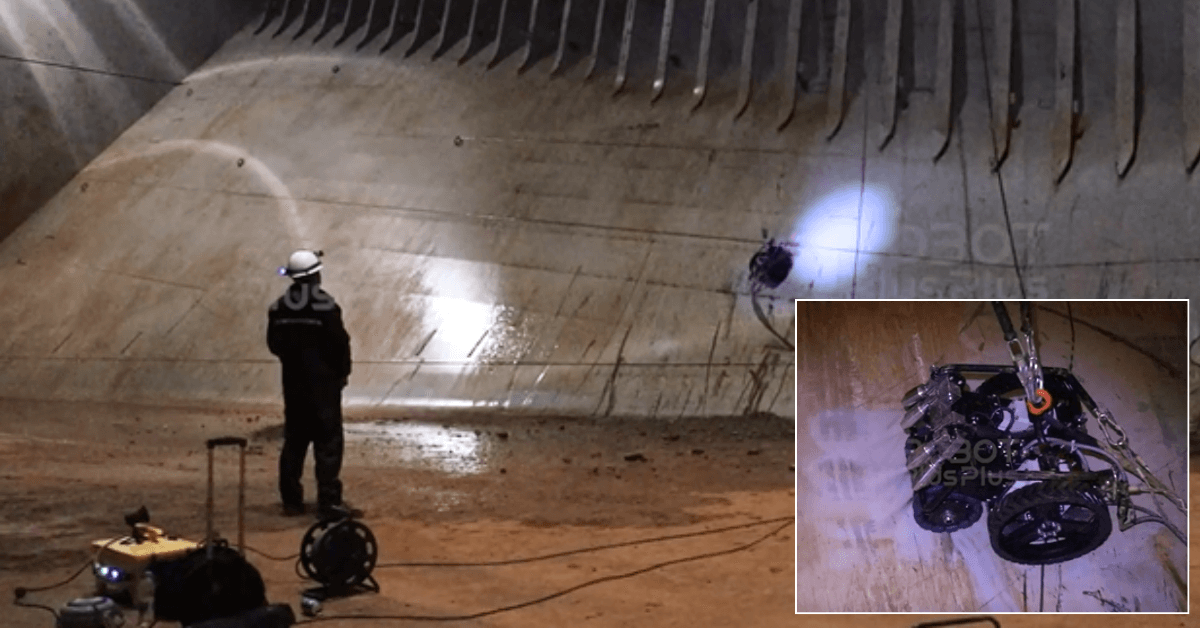

RobotPlusPlus has unveiled its latest advancements in maritime robotics at Sea Asia 2025, currently taking place at the Marina Bay Sands Convention Centre in Singapore.

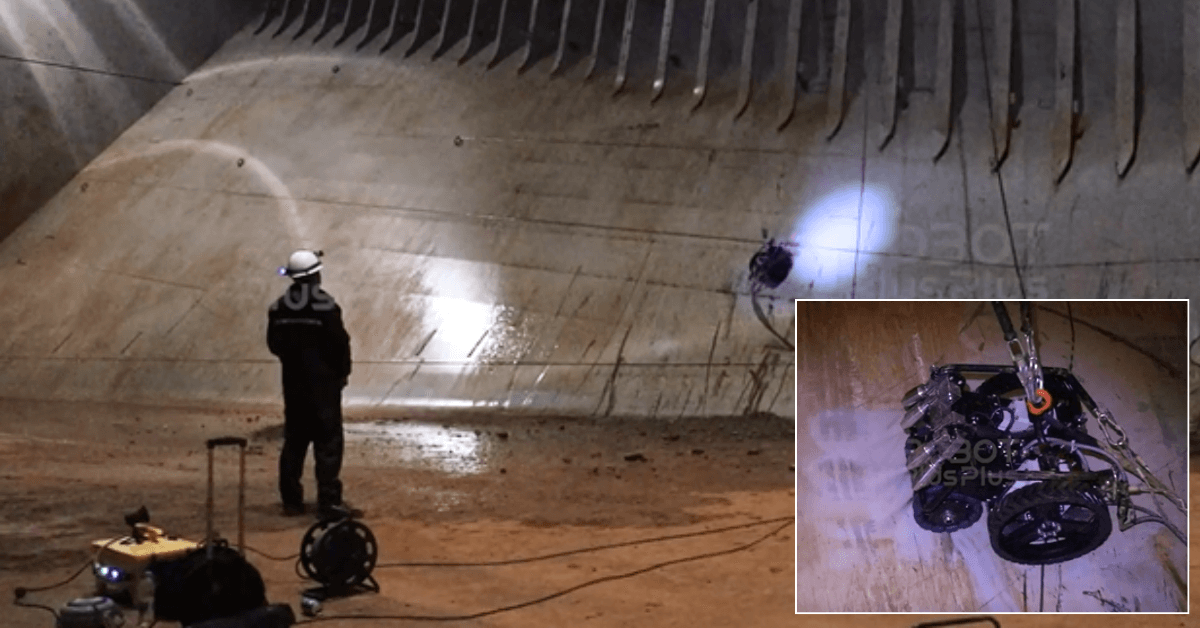

The company is demonstrating the HighMate C20 Cargo Hold Cleaning Robot, designed to tackle the complex and labor-intensive process of cleaning cargo holds, particularly those carrying nickel ore.

Nickel ore presents major cleaning challenges due to its high moisture content, which makes it sticky and difficult to remove. The ore also tends to accumulate in corners and crevices, creating further complications. It adheres to cargo hold surfaces, requiring a lot of effort and time to clean manually.

The HighMate C20 is built to simplify and speed up the cleaning process. It covers up to 95% of a cargo hold’s surface, reducing the risks associated with manual cleaning at heights.

One of its key advantage is its ability to operate even with a closed cargo hatch, eliminating the need for cherry pickers and other manual equipment.

Video Credits: RobotPlusPlus/Linkedin

The robot’s user-friendly design ensures that seafarers can learn basic functions in just 10 minutes, making it highly accessible for ship crews.

This robotic solution is on display at Booth B2-Q25, where visitors can witness live demonstrations of its capabilities. The HighMate C20 first made its debut at SMM 2024 in Germany, and its advanced driving controls and flexible navigation make it highly effective in confined spaces.

RobotPlusPlus is also presenting the HighMate AP Series Multi-Function Robot, which is built for blasting and coating steel surfaces. This model is reported to be four times more efficient than traditional manual methods and is certified under ATEX and IECEx standards for safe use in explosive environments.

Other advanced robotic models on display at the event include:

– HighMate S10R Coating Robot– A specialised robot designed for steel coating applications.

– HighMate V45 Hydroblasting Robot– A surface preparation robot that operates autonomously using hydroblasting technology.

A spokesperson from RobotPlusPlus stated that manual cargo hold cleaning is both dangerous and labor-intensive, and automation provides a safer and more efficient solution for the maritime industry.

Reference: RobotPlusPlus

Source: Maritime Shipping News